The Major Benefits of Using Membrane Switches in Manufacturing

Why Membrane Switches Over Are Crucial for Durable Control Systems

Membrane switches play a critical duty in ensuring the durability and reliability of control systems throughout numerous markets. Their special building allows them to endure challenging ecological variables such as moisture, temperature level extremes, and physical wear. This resilience not just prolongs the lifespan of the systems they offer yet likewise decreases upkeep requirements. As we explore the complex benefits of membrane switches, it comes to be obvious that their importance goes beyond plain functionality, affecting individual experience and operational effectiveness. What more ramifications do these characteristics hold for the future of control system design?

Introduction of Membrane Layer Switches

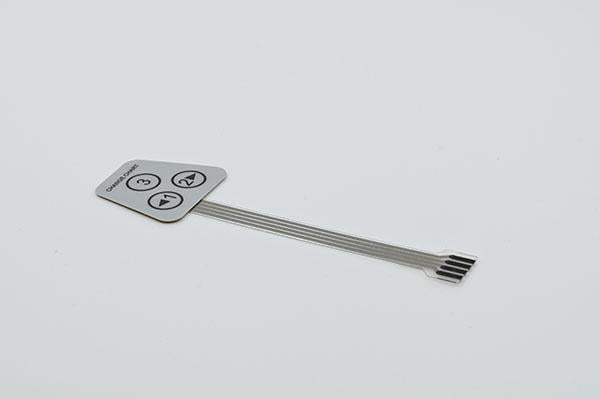

Membrane switches are flexible and reliable elements generally utilized in various digital control systems. These switches contain several layers, consisting of a graphic overlay, a spacer layer, and a printed circuit layer. The graphic overlay offers both practical and visual layout, while the spacer layer makes certain that the switches are triggered just when pressed. The published circuit layer contains conductive traces that complete an electrical circuit when the membrane is pushed, making it possible for the tool to reply to user inputs.

Membrane switches are typically favored in applications needing a compact and light-weight style, making them perfect for portable gadgets, medical equipment, and industrial equipment. They can be tailored to fulfill particular individual needs and can include different functions such as backlighting, tactile feedback, and numerous shades. Moreover, membrane layer buttons are immune to dust, moisture, and contaminants, making them appropriate for atmospheres where longevity is essential.

Benefits of Sturdiness

In numerous applications, the durability of membrane layer switches offers considerable benefits that boost their general efficiency and integrity. These buttons are created to endure harsh atmospheres, making them optimal for usage popular conditions such as high moisture, severe temperature levels, and direct exposure to chemicals. Their robust construction aids to avoid damage from physical impact, making certain resilient performance and decreasing the requirement for frequent replacements.

In addition, membrane switches are resistant to damage, which is critical in applications where constant interaction happens. This durability translates to lower maintenance expenses, as companies benefit from minimized downtime and less solution interruptions. Moreover, the encapsulated style of membrane changes safeguards internal elements from dust and wetness ingress, further adding to their life-span.

An additional benefit is their capability to maintain regular performance gradually. With a high tolerance for mechanical stress, these switches preserve their tactile comments and electrical integrity, making sure customer fulfillment. Inevitably, the sturdiness of membrane layer changes not just enhances functional efficiency however additionally promotes self-confidence in their dependability, making them a recommended option for control systems throughout numerous industries.

Applications in Numerous Industries

Long lasting control systems employing membrane switches discover substantial applications across a range of sectors, each profiting from the one-of-a-kind features these switches provide. In the medical field, membrane switches are essential for tools such as person displays and analysis devices, where dependability and simplicity of cleansing are extremely important. Their resistance to wetness and impurities ensures they preserve functionality in sterile environments.

The vehicle market leverages membrane buttons for dashboard controls and infotainment systems, where they offer smooth, low-profile user interfaces that enhance individual experience. These switches are also made to stand up to harsh problems, including direct exposure to severe temperature levels and resonances.

In commercial setups, membrane layer switches are typically utilized in machinery control panels, offering tactile comments and durability required for high-usage applications. Their capability to stand up to chemicals makes them ideal for manufacturing environments where spills and impurities are constant.

Customer electronic devices, such as kitchen home appliances and remotes, also use membrane layer switches for their convenience and cost-effectiveness. Generally, the adaptability and robust nature of membrane layer switches over make them essential throughout numerous sectors, making certain efficient operation and durability in control systems.

Design and Visual Appeal

While capability is critical, the layout and aesthetic charm of control systems outfitted with membrane layer buttons play an essential role in customer interaction and total experience (membrane switch). The visual style of these buttons can considerably affect individual continue reading this understanding and interaction. A well-designed membrane switch enhances the appearance of the gadget, making it extra attractive to users and fostering a link between the individual and the item

Membrane layer changes offer a large amount of versatility in design, enabling producers to tailor graphics, shades, and textures to straighten with brand identification and product aesthetic view it now appeals. The usage of lively colors and distinctive patterns can attract attention, while responsive responses can enhance the user's communication with the gadget. In addition, the capacity to integrate LED indicators and backlighting right into the membrane switch style provides both functional and aesthetic benefits, enhancing visibility and functionality in various atmospheres.

Enhancing Customer Experience

Furthermore, membrane layer switches can be personalized to include graphical user interfaces, improving usability by providing info in a clear and user-friendly way (membrane switch). This customization can consist of symbols, tags, and color coding that guide individuals through complicated functionalities easily. Furthermore, their flexibility enables integration in various environments, ensuring regular efficiency whether in commercial machinery or consumer electronics

The resilience of membrane switches also plays a crucial function in customer experience. By enduring extreme problems and prolonged usage, these buttons reduce the probability of system failings, thus promoting dependability and customer self-confidence. Inevitably, look these up the calculated use of membrane switches over not just raises capability yet also considerably enriches individual communication with control systems, making them an essential element in contemporary design.

Conclusion